Due to the excellent characteristics of LED display, more and more people choose to use LED screens as display devices, and LED display industry has gradually occupied the market share of traditional LCD displays. So how to distinguish whether the LED video wall is good? How to choose a suitable brand? First of all, we must understand the problems that exist in LED video wall industry.

itc is positioned to make system products that solve common problems and pain points in the industry, serve customers with high-quality products, and lead the industry.

itc LED Video Wall for REINZ and YPIRE Conference Project

First of all, itc implements customized production for color difference. Most LED manufacturers adopt wholesale production, and products are stored in warehouses after aging and packaging. In this way, LED screens purchased by customers may be produced in multiple batches, which is prone to color differences. However, itc produces on single project basis and does not keep inventory, which ensures that the chips are in the same batch without color difference.

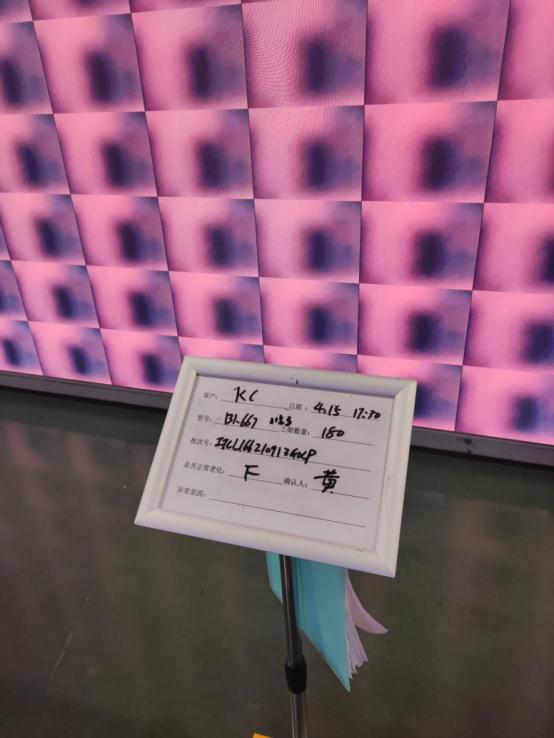

After controlling the color difference, the problem of parametric seam is also solved by 80%. In order to completely eliminate seams, itc owns a patent - seamless calibration technology. During production and debugging, we will use a professional engineering camera to shoot the LED screen of different areas from 15 different angles. After obtaining parameters, adjust the parameters of each splicing screen to the same standard value, achieving the perfect seamless display.

The most troublesome part of LED video wall is anti-moisture. itc uses the nano-coating technology developed by ourselves, just like wearing a suit of armor for the screen, which solves the dust-proof and moisture-proof problems, and also prevents screen deformation caused by temperature difference, providing great protection on the display screen in a humid environment and ensuring the lifespan of the screen.

Nano-coating Machine

Finally, the quality of LED video walls that customers are most concerned about depends on the lamp beads, cabinet, and construction technology, which determine the lifespan of screen.

The most critical raw material for LED screens is lamp beads. The stability of the lamp bead directly determines the stability of the screen. Our factory has done a lot of tests and eliminated many lamp beads with poor stability. Finally, we decided to use only Nationstar and Kinglight, which are the most stable lamp beads in the industry, focusing on making stable screens.

Scanner

itc is equipped with die-cast aluminum cabinet or standard sheet metal cabinet, all with back cover, which has good heat dissipation performance and good flatness, greatly protecting the wire. Some merchants usually provide simple iron cabinets without back cover. This is actually a potential safety hazard. One is that the iron is easy to oxidize and rust; the other is that the wires are all exposed. It is easy to cause short circuit of the screen due to biting of mice; in addition, it is impossible to achieve complete seamless splicing because of poor flatness.

Fully Automatic Production Workshop

itc is not just as simple as selling a screen to you but will give you a professional solution from the aspects of stability, service life, safety, and humanization so that users can feel at ease during use. At the same time, we also provide after-sales service, guaranteeing the normal operation of the product.