Providing customers with high-quality system solutions is the core advantage of itc, and LED product is only a part of it. Our LED products are independently designed and produced, with better pre-sale, in-sale, and after-sale services, to better realize the high integration and stability of the solution. That is Engineering Mode Sales.

| C series | ||

| Model | C1.53 | C1.86 |

| Pixel pitch | 1.53mm | 1.86mm |

| Resolution | 422500 pixels/m² | 288906 pixels/m² |

| Refresh rate | ≥3840Hz | ≥3840Hz |

| Brightness | 200-600CD/m² | 200-600CD/m² |

| Contrast | ≥10000:1 | ≥10000:1 |

| Cabinet size | 640*480mm | 640*480mm |

| Module size | 320*160mm | 320*160mm |

| Cabinet material | Die-cast aluminum/module | Die-cast aluminum/module |

| Protection class | Die-cast aluminum enclosure IP5X | |

| Average power consumption | ≤168W/m² | ≤168W/m² |

| Max power consumption | ≤500W/m² | ≤500W/m² |

In no plastic bottom case design, the edge of the PCB directly contacts the four sides of the die-casting cabinet for heat conduction, which can reduce the temperature by 5-10° compared with the plastic bottom case products, and eliminate the phenomenon of color drift. It directly fits the die-casting aluminum cabinet with better flatness, thinner thickness, and better appearance.

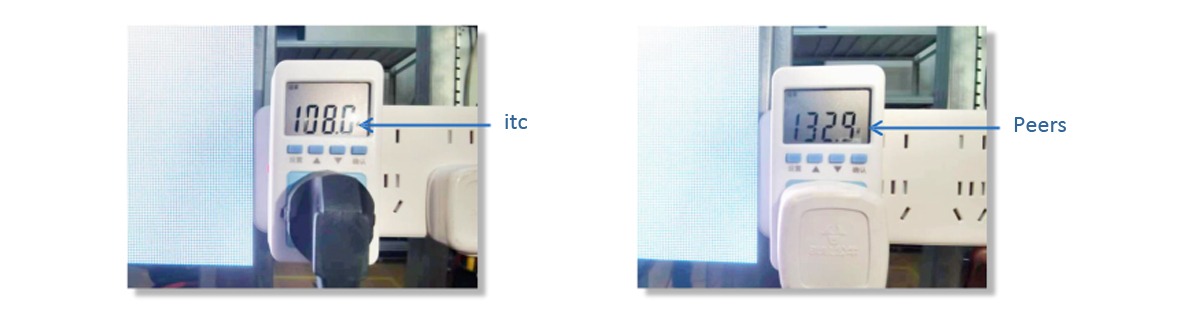

| Test (C1.86) | Peer 1 | Peer 2 | itc | |

| White Screen Brightness 100% | Brightness cd/ ㎡ | 600 | 600 | 600 |

| Cabinet power consumption W/pcs | 132.9 | 153 | 108 | |

| Maximum power consumption W/ ㎡ | 433 | 500 | 352 | |

| Average power consumption W/ ㎡ | 108 | 125 | 88 | |

| Working voltage | DC

+4.2V~+5V |

DC

+4.2V~+5V |

DC

+2.8V~+3.8V |

|

Example: conference room → 20㎡ screens → calculated based on 8 hours of usage per day (average power consumption) Peer 1: 20×108×8=17280W Peer 2: 20×125× 8= 20000W itc: 20×88×8=14080W Result: Compared with peer 1, itc saves 3200W power, about 19%; compared with peer 2, itc saves 5920W power, about 30%.

Since the actual power supply required by the RGB chip is R 2.8V, G3.8V, and B3.8V, the excess power supplied by the 5V power will be wasted (converted into heat energy). Therefore, the common anode low-voltage power supply can better achieve energy-saving effect and eliminate a large amount of heat dissipation during the use of the screen.

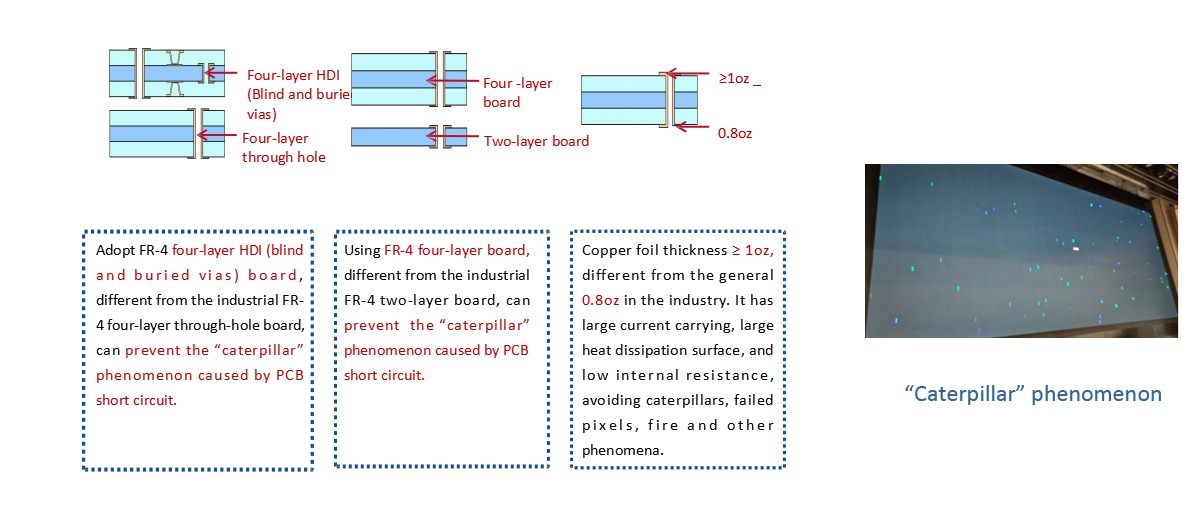

In order to eliminate the hidden fire safety hazards in terminal use, itc PCB boards all reach the V-0 flame retardant grade, which can completely eliminate fire accidents compared with the V-1 grade of the competitors in the market.

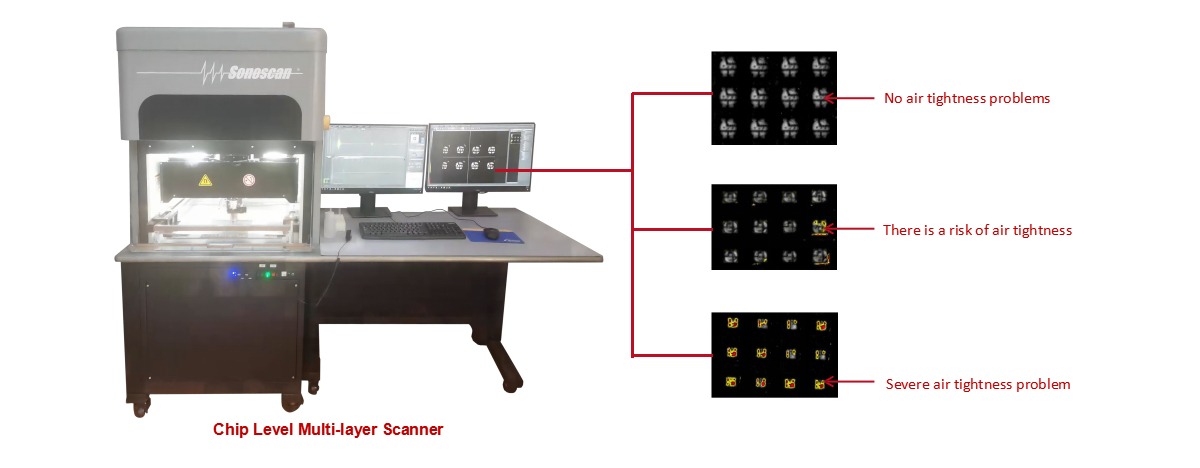

Imported million-level chip multi-layer scanner For each batch of incoming LED lamp beads, we will make the first piece for layered scanning before mass production, and intuitively detect whether the batch of materials has problems such as air tightness, so as to prevent the occurrence of caterpillars and dead pixels in the products in the later use.