In a meeting, documents, tabular data, and PPT are usually used to explain the views, summaries and planning, and most of these documents have a white background. As we all know, the temperature of the LED display screen is the highest when it is white. Affected by various factors, the heat dissipation of the LED module is uneven, resulting in color drift.

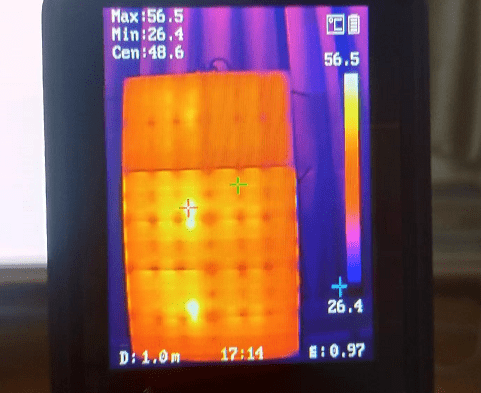

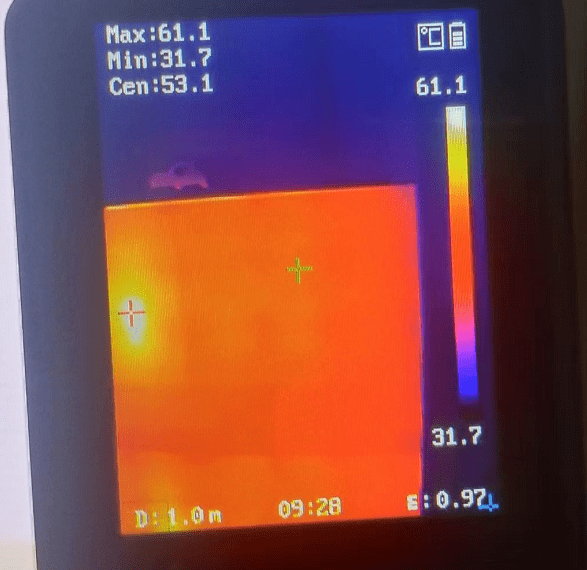

Aiming at the pain points, itc R&D team has devoted itself to the testing and comparison of the core components of led panel manufacturers. Numerous experiments have shown that heat dissipation of cabinet, arrangement of IC, and contact between accessories and PCB board will form a temperature difference, leading to varying degrees of color drift.

Welding positioning posts, iron sheets, and assembled sheet metal shells on LED modules will also accelerate heat conduction when in contact with the PCB, so it is necessary to design heat insulation pad on the contact surface with the PCB board or reduce the contact area;

Select appropriate main components such as lamp beads, ICs, and power supplies according to requirements. The load of each component should be left with margin.

Based on the above experimental conclusions and design solutions, the LED module has uniform color rendering, no spots, no streaks, and no ghosting in the white test.

itc high-definition LED display is widely used in governments, campuses, cultural and sports venues, enterprises and so on, meeting the playback requirements of high-intensity, high-precision, and high-quality images. With superior color performance and excellent product quality, it presents a wonderful visual experience!