When you walk into itc's LED manufacturing plant, you can see that every employee wears a metal bracelet on their hand, which is called a static bracelet. It can completely isolate the static electricity produced by the human body on the LED impact, the role can not be underestimated. Next, take you to understand the harm caused by electrostatic discharge to LED.

In the semiconductor industry, more than 10% of product failures are attributed to electrostatic discharge (ESD) influence. Products are worn, burned, degraded and destroyed by electrostatic discharge, which is one of the main causes of product problems. Electrostatic discharge damage mainly electronic components or systems in the manufacturing, production, assembly, testing, handling and other processes, static electricity will accumulate in the human body, instruments, and even electronic components themselves, the mutual contact between these objects, forms a discharge path so that electronic components or systems were permanently damaged by electrostatic discharge, which brings great difficulties to LED video wall production.

As we all know, LED driver IC is the heart of the whole display screen, and the life of the driver IC directly determines the life of the display screen. If the heart is damaged, the screen is bound to fail. Therefore, itc makes great efforts in the electrostatic protection of IC. PCB board edges are all surrounded by GND, ESD protection circuit is added, and the enclosure of the equipment is connected or directly grounded. The algorithm is optimized to make ESD protection have fast response time, low clamp voltage, and withstand the repeated action of ESD without damage.

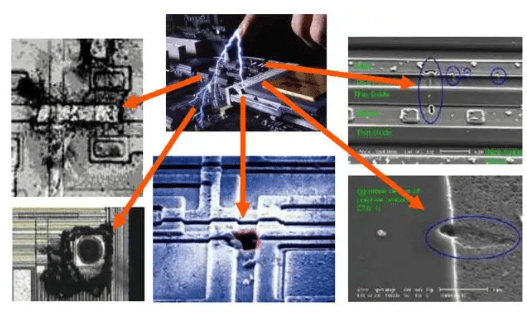

After the LED driver, IC is damaged by static electricity, the semiconductor component is severely damaged

According to the different ways of electrostatically charged bodies and their discharge to IC, electrostatic discharge phenomena can be divided into the following two categories:

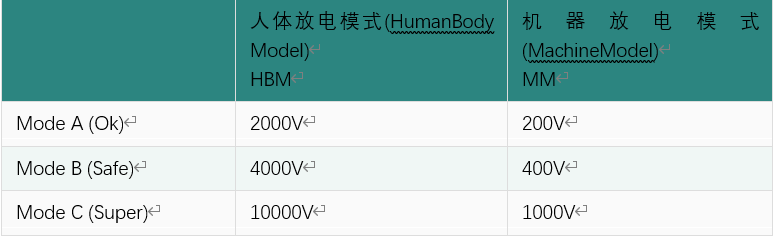

The following table lists the ESD specifications of integrated circuits. General commercial specifications of integrated circuit products should have at least human discharge 2KV, MM 200V protection ability.

Human body discharge mode (HBM) ESD refers to the accumulation of static electricity caused by the human body walking on the ground friction or other factors. At this time, the static electricity of human body will enter the IC through the IC foot (pin), and then discharge from the IC to the ground, as shown in the figure. This discharge process generates a transient discharge current of several amperes in a time as short as a few hundred nanoseconds (ns), which burns the components within the IC. For the 2-KVESD discharge voltage of a general commercial IC, the peak instantaneous discharge current is about 1.33 amps.

Machine discharge mode (MM) ESD refers to the accumulation of static electricity in the machine (such as the mechanical arm) itself. When it touches the IC, the static electricity will be discharged through the pin of the IC. The equivalent circuit diagram is shown in the figure.

Because most machines are made of metal, the equivalent resistance of the machine discharge mode is 0Ω, but its equivalent capacitance is set at 200pF. Because the equivalent resistance of the discharge mode of the machine is 0, the discharge process is shorter, and several amps of instant discharge current can be generated within a few nanoseconds to tens of nanoseconds.

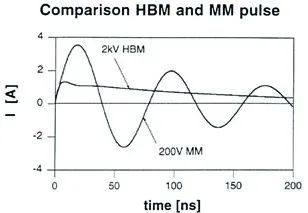

Although the human body discharge voltage of 2KV is larger than the machine discharge voltage of 200V, the discharge current of 200V machine discharge is much larger than the discharge current of 2KV human body discharge, so the machine discharge mode is more destructive to IC.

As shown in the figure, the discharge current waveform of the 200V machine has the condition of up and down vibration, which is caused by the mutual coupling of the stray equivalent inductance and capacitance of the test machine conductor.

Comparison of discharge current between human body discharge mode (2KV) and machine discharge mode (200V)

Electrostatic damage can lead to the failure of a number of IC, heavily leading to early aging of the entire electronic system, reliability reduction, or immediate fire and explosion.

The ESD voltage resistance of an IC is defined as the minimum voltage tolerance value of all its pin pins. In order to avoid the harm caused by electrostatic damage, the IC selected by itc has the tolerance ability of human body discharge mode 3.5KV and achieves the effect and purpose of electrostatic protection by controlling the production environment and a series of effective measures. Multiple electrostatic protection modes ensure the absolute perfection and safety of the LED production process, ensuring the high-quality output and use of each product so that the LED display is in the hands of customers and plays the maximum value.

Electrostatic protection is only a part of itc's production control of small-space LED. In the whole production process, itc always keeps a high quality, high specification and high standard, and eliminates all kinds of hidden dangers in production and quality, so as to ensure that each output display screen is flawless and without damage, providing the best presentation tool for customers' visual perception. Bring shock three-dimensional, panoramic immersion visual feast!