As the widespread application of LED display screens continues, there is a growing demand for higher product quality and display performance. Traditional SMD technology is no longer sufficient to meet the requirements of certain scenarios. As a result, some manufacturers have turned to COB and other technologies or have improved upon SMD technology, with GOB technology being an iteration of SMD encapsulation.

Can GOB technology facilitate a more extensive range of LED display screen applications? How will GOB technology develop in the future market? Let's explore these questions!

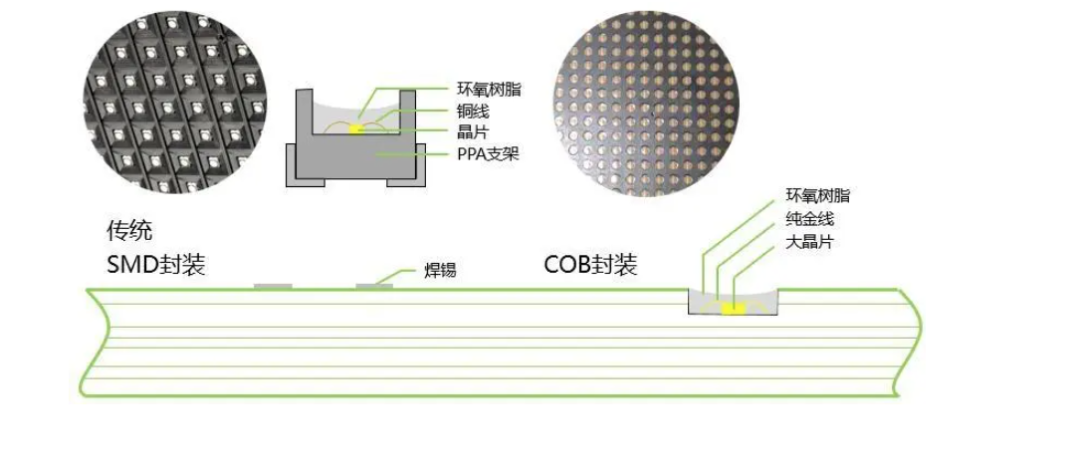

Since the development of the LED display screen industry, various encapsulation techniques have emerged, including COB displays. These range from through-hole (LAMP) technology to surface-mount (SMD) technology, and now encompass COB encapsulation technology and GOB encapsulation technology.

COB encapsulation technology involves directly affixing LED chips onto a PCB substrate for electrical connection. It primarily addresses the heat dissipation issue in LED display screens. Compared to through-hole and SMD technologies, COB encapsulation offers advantages in terms of space utilization and simplified packaging operations. Currently, COB encapsulation is mainly utilized in products with small pixel pitches.

GOB encapsulation technology is a protective packaging technique for LED chips. It utilizes advanced transparent materials to encapsulate the PCB substrate and LED packaging units, effectively providing ten forms of protection: waterproof, moisture-proof, impact-resistant, scratch-resistant, anti-static, salt-resistant, anti-oxidation, blue-light-blocking, and vibration-resistant.

The disparity between COB and GOB lies in the differences in their manufacturing processes. While COB encapsulation offers a smooth surface and superior protective properties compared to traditional SMD encapsulation techniques, GOB encapsulation incorporates a gluing process on the surface of the screen, providing greater stability to the LED chips and significantly reducing the risk of lamp failure, thereby enhancing overall stability.

Both COB and GOB have their respective advantages, and there is no definitive standard to determine which encapsulation technology is superior. The choice between COB and GOB encapsulation depends on a comprehensive evaluation of factors such as the installation environment, duration of usage, cost control considerations, and disparities in display performance.